CASEIFICIO GIOVANNI INVERNIZZI’S manufacturing plant has six main areas:

- Administrative offices

- Retail outlet

- A chemical laboratory for microbiological analysis

- Cheese factory

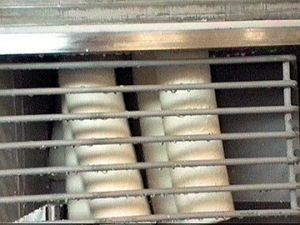

- Storage room and maturation room for soft cheese

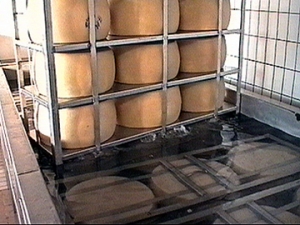

- Grana Padano and Gran Lombardo maturing storehouse.

Our bulk milk

The milk we use is 100% Italian milk, produced in selected Lombardy cowshed, regulated by norms to guarantee neutrality and hygiene of the product.

Each daily owner farmer delivery is subject to rigorous preliminary analysis to establish milk acidity and temperature, to verify the presence of inhibitory substance: only if all our quality standards have been satisfied, the milk is suitable for successive transformations.

Only milk passed our preliminary analysis can be finally use for our different productions according to the seasonal market availability.

Furthermore, our milk is testing several times during the year:

Lombardia and Emilia Romagna Institute for Disease Prevention in Domestic Breeding Herds, located in Brescia, twice a year certified the milk quality profile (fats, proteins, total bacteria count, somatic cells count and cryoscopy index) and once a year, we examine the bulk milk in order to guarantee the absence of any aflatoxin contents (M1 and PCB).

Production line

Caseificio Giovanni Invernizzi has three main production line:

Grana Padano and Gran Lombardo line: These two semi-fat long-maturation hard cheeses are obtain from a natural process of surface skimming which takes place in special tanks. The main difference between these two types of cheese are the production method: Grana Padano is produce using exclusively raw milk, in compliance with the Grana Padano Protection Consortium disciplinary directions; Gran Lombardo is obtain from heat-treated milk.

Soft and semi-soft cheese line: The main ingredient of this type of cheese is completely pasteurized milk. The production take place in a polyvalent closed cradle machinery equipped with a special cutting and shaking member. The most of the production stages are the same for all products of this line but the recipes change in type of ingredients (enzymes, starters’ cultures and cheese rennet), production times and temperatures (manufacturing, steaming, salting and maturation temperature). Finally, each type of cheese has its own characteristic form or shape.

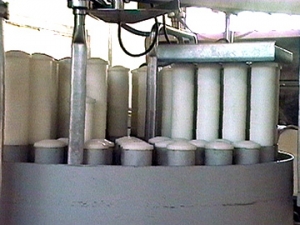

“Pasta filata” cheese line (stretched-curd cheese line).

Completely pasteurized milk is the basic ingredient of this group of cheese whose paste are subject to a special process, named stretching in hot water. From this line, we obtain Mozzarella cheese and Mozzarella blocks for pizza (Soffilat). The process of acidification of the paste is naturally reached thanks the acidifying action of selected enzymes.

List of our cheeses

- Taleggio DOP

- Quartirolo Lombardo DOP

- Gorgonzola DOP (Dolce/Piccante)

- Grana Padano DOP

- Gran Lombardo

- Crescenza

- Mozzarella block (Pizza-cheese da 1,2 kg)

- Robiola

- Bergamella piccola

- Bergamella

- Tomì

- Primo Sale

- Latteria

- Mascarpone

- Bocconcini di mozzarella

- Ciliegine di mozzarella

- Mozzarella di bufala

- Ricotta

- Mozzarella cubes

- Burro

Other cheeses for sale

- Julienne

- Goat cheese

- Maasdammer

- Pecorino Romano DOP

- Piave

- Provolone

- Emmental/Trancio occhiato

- Brie

- Mozzarella di bufala